Product Description

IPS-S1 is a high-performance motor controller that integrates multiple functions, mainly used to control electric linear actuators. The S1 controller is compatible with DC6V~36V, and the maximum current can reach 20A. The positive and negative poles need to be wired according to the wiring diagram. If the positive and negative poles are connected incorrectly, it will not worked, While it will not burn the controller. Such as 60W linear actuator, please choose a 60-90W power adapter/switching power supply, if use a smaller power, it may cause the motor to not work. S1 controller can be used to control various specifications of electric linear actuators, built-in WIFI module, can be controlled by 'eWeLink' APP, only supports 2.4G WIFI. There is a learning button inside the controller, which can learn 8 pcs RF433 remote controllers. There are 6 buttons K1 K2 K3 B1 B2 L on the controller, K1 K2 K3 is used to adjust various functions, please see below for detailed instructions. The B1 B2 button controls the motor forward and reverse; the L button learns WIFI. IPS-S1 controller can be controlled by magnetic induction switch, human body induction switch, button switch, or through PLC/PC.

Technical Parameters

| Model | IPS-S1 | WIFI Standard | Wi-Fi 2.4ghz b/g/n |

| Input Voltage | DC 6V-36V | Remote Control Battery | 23A 12V |

| Output Voltage | DC 6V-36V | Working Temperature | -20°C~ +70°C |

| Maximum Current | 20A | Storage Temperature | -20°C~ +90°C |

| Receiving Frequency | RF433MHz | Working Humidity | <80% |

| Key Mode | Press Once Continuous Work |

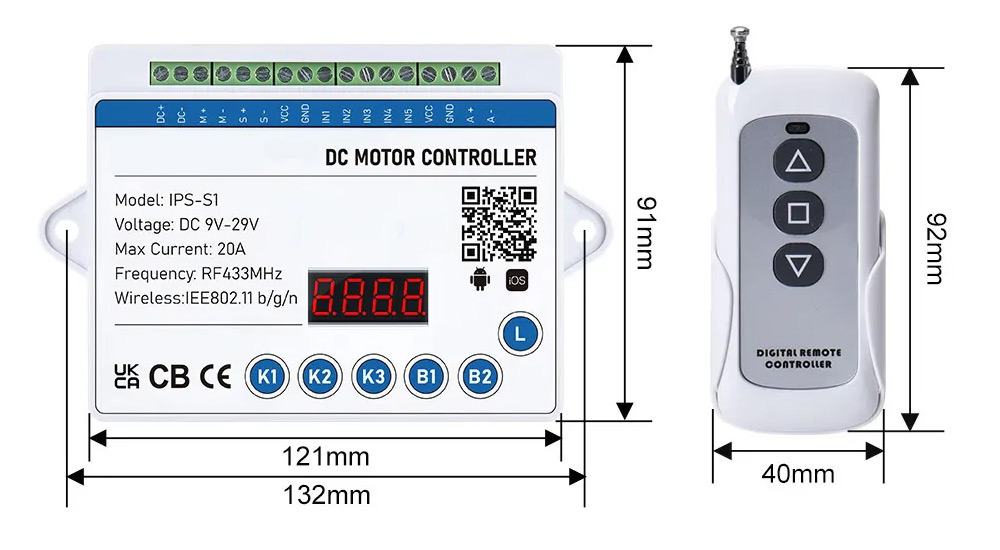

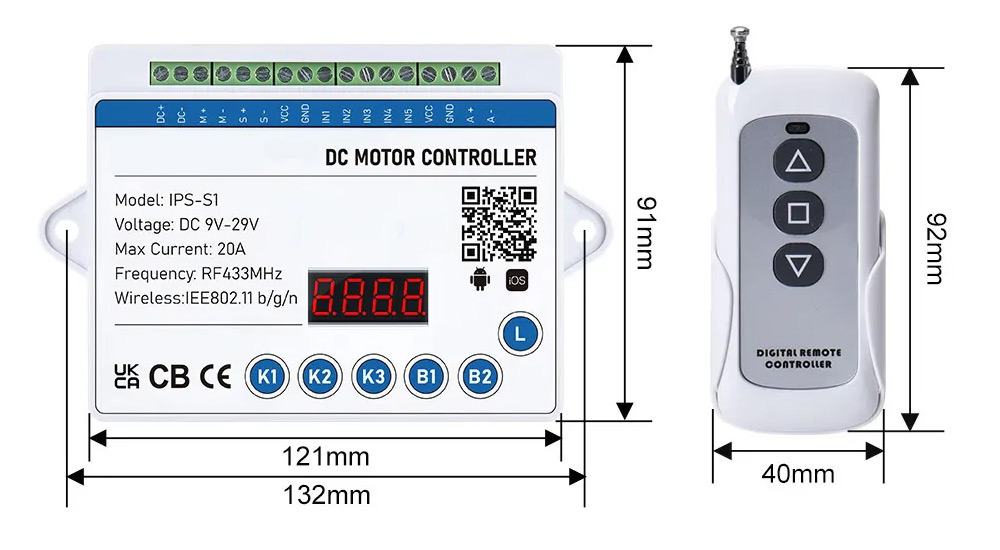

Dimensions

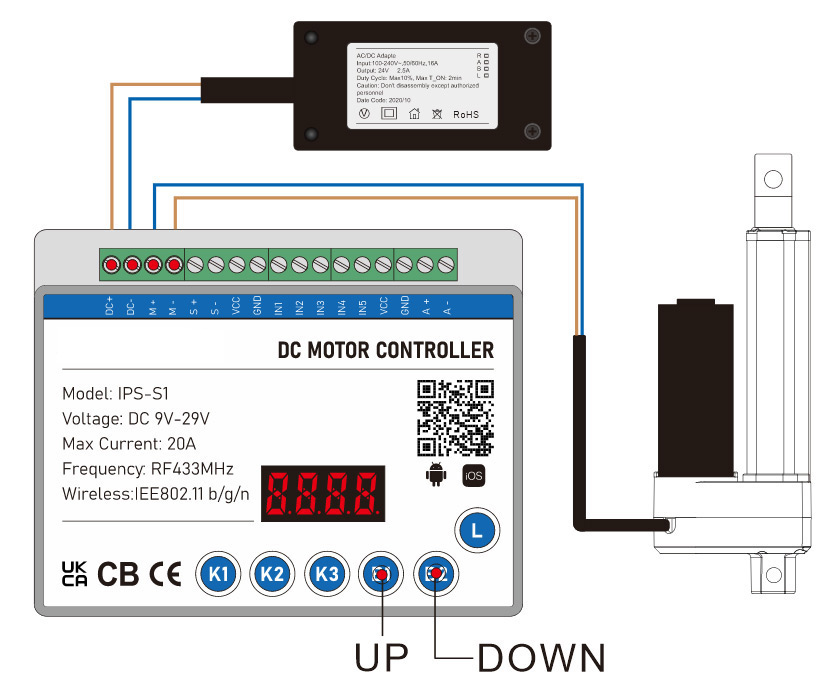

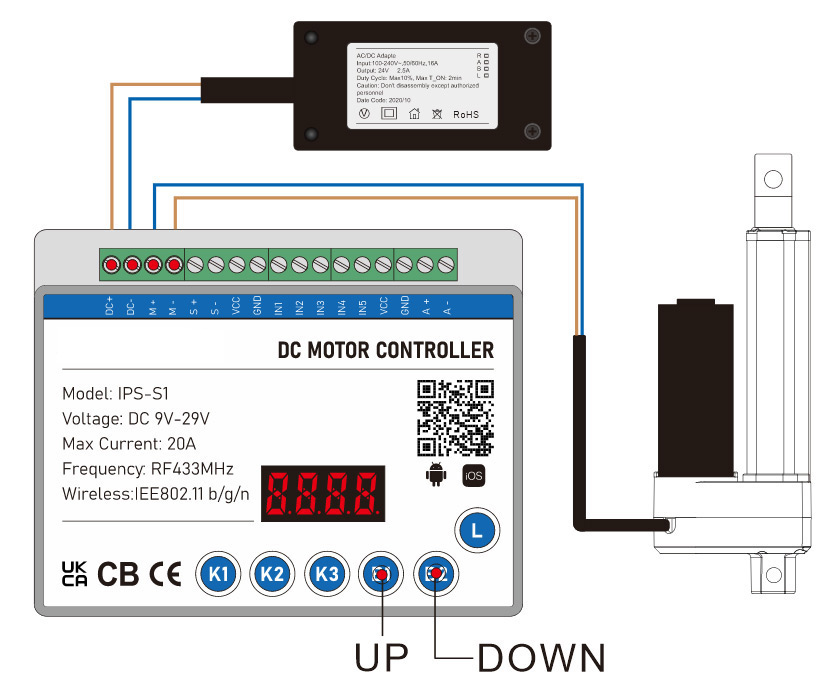

Wiring Instructions

The Main Functions

1. Motor forward and reverse control: press B1 to rotate forward to rise, press B2 to reverse reverse to descend, if it’s not correct, please switch the 2 power lines of motor.

2. Remote control control: It can be adapted to RF433 remote control (three keys: forward, pause, reverse), one controller can be equipped with 8 remote controls. (only one remote control is provided by default)

3. Hand controller control: You can purchase our 2.5m hand controller for control.

4. WIFI control: You can connect 2.4G WIFI through the L button for lifting control. (The remote signal is easy to lose, controller needs to be as close to the router as possible)

5. PLC control: you can purchase our PLC all-in-one touch panel for control, or you can write a program to control.

6. PC host computer control: need to purchase USB to RS485 communication data cable, and need to install RS485 serial port software on the computer for control.

7. induction control: need to purchase photoelectric induction switch to connect, through K1 key to set the program.

8. Button control: you need to purchase a button switch for connection, and set the program through the K1 key.

9. Timing control: press the remote control once, the motor will automatically stop after running for a fixed time.

10. Magnetic switch limit control: The electric actuator needs to have a built-in magnet, and a magnetic induction switch needs to be purchased for connection, and the lifting height can be adjusted according to the needs.

11. Limit feedback: Five-wire control electric actuator is required, and the operating status of the actuator can be inquired, and feedback can be obtained through the signal.

12. Overload protection: Set the maximum current of the controller through the K2 button, when the motor exceeds the current, it will stop.

13. Rebound in case of resistance: set the current through the K2 button, when the electric actuator encounters an obstacle, the current increases, the controller will stop work

| FUNCTION INTRODUCTION |

| 1 | Lock Controller | Press B1 and B2 buttons simultaneously for 3 seconds |

| 2 | Unlock Controller | Press B1 and B2 buttons simultaneously for 3 seconds |

| 3 | Timing Control | Press K3 button for 3 seconds

3A: Set up running time (press once up button)

3B: Set down running time (press once down button) |

| 4 | Overload Protection | Press K2 button for 3 seconds

2A: Up Current Limiting Value (0.1-999.9)

2B: Down Current Limiting Value(0.1-999.9)

2C: Protection Type ( 0-Stop, 1-Reverse Running)

2D: Current Filtering Time (0.1-999.9) |

Explain: set 2A-3;2B-3;2C-0;2D-0.1;

When the up running current reaches 3A, it will stopped;

The filtering time is 0.1 seconds without current limiting (The starting current of the motor will be large) |

| 5 | Rebound When Obstructed | Press K2 button for 3 seconds

2A: Up Current Limiting Value (0.1-999.9)

2B: Down Current Limiting Value(0.1-999.9)

2C: Protection Type ( 0-Stop, 1-Reverse Running)

2D: Current Filtering Time (0.1-999.9) |

Explain: set 2A-3; 2B-3; 2C-1; 2D-0.1;

When the up running current reaches 3A, it will run in the reverse direction for 1s and stopped;

The filtering time is 0.1 seconds without current limiting (The starting current of the motor will be large) |