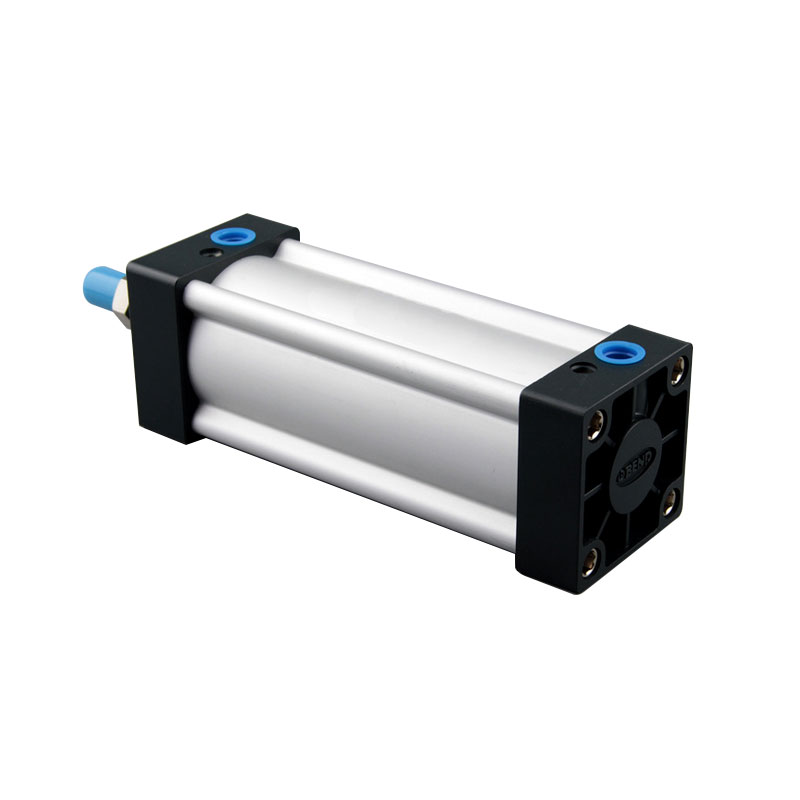

Pneumatic valves are now more and more widely used in various industries. The technology of

pneumatic cylinder actuators is also getting better and better. The gap between domestic pneumatic cylinder actuators and imported pneumatic cylinder actuators is getting smaller and smaller, and the types of pneumatic cylinder actuators are becoming more and more. Introduce several inspection methods of pneumatic cylinder actuator for you.

1. Fix the pneumatic cylinder actuator on the calibration table, connect the air source, control the air source and displacement detection connecting rod respectively, and adjust the instrument on the calibration table accurately.

2. Mechanical zero point calibration: input 4mA current signal (0%) and control gas signal should be 0.02Mpa, at which time the stroke of cylinder piston should be zero; if not, zero point can be adjusted by adjusting the nut on the zero adjusting screw (zero point is higher than the tight nut); zero point and range need to be adjusted repeatedly; zero error should be less than 1%;

3. Full-range calibration of machinery: input 20 mA current signal (100%) and control gas signal should be 0.10 Mpa, at which time the stroke of cylinder piston should be the upper limit value; if not, the range can be adjusted by adjusting the tension of the range spring (the range is smaller, the range is larger, the tension spring); zero point and the range need to be adjusted repeatedly; the full-range error should be less than 1%;

4. Medium point positioning of mechanical range: after zero point and range alignment, input 12 mA current signal (50%, 0.06 Mpa) and adjust the position of the connecting rod of the position transmitter to keep it perpendicular to the horizontal plane.

5. Full stroke deviation calibration: input control gas signal 0.02Mpa (0%) and then gradually increase input signal 0.036 Mpa (20%), 0.052 Mpa (20%), 0.068 Mpa (60%), 0.084 Mpa (80%) and 0.1 Mpa (100%) to make the cylinder and piston complete stroke with deviation of less than 1.5%.

6. Nonlinear deviation test: input control gas signal 0.02 Mpa (0%) and then gradually increase the input signal until 0.10 Mpa (100%) and then reduce the signal to 0.02 Mpa (0%) so that the actuator can complete the journey, and record the travel value corresponding to the increase or decrease of 0.008 Mpa signal pressure. The non-linear deviation between the actual pressure-stroke relationship and the theoretical value is less than 1%;

7. Measurement of positive and negative stroke variation: The maximum difference between positive and negative stroke values of cylinder piston under the same pressure value is less than 1% in the actual positive and negative pressure-stroke relationship, which is the same as that of the non-linear deviation test method.

8. Sensitivity test: increase and decrease the pressure at the stroke of signal pressure 0.03, 0.06 and 0.09 Mpa, respectively. Test the change of signal pressure needed when the cylinder piston rod begins to move 0.1 mm, and the maximum change is less than 0.2%.

9. Sealing test of piston cylinder: Put 0.5 Mpa pressure into any air chamber of the cylinder, then cut off the air source. Within 10 minutes, the pressure drop in the cylinder should not exceed 0.01 Mpa;

10. Position transmitter electrical Zero detection: open the upper cover of the position transmitter and connect the wire; input 12 mA current signal (0.06 Mpa), then adjust the circular eccentric wheel in the transmitter to align the black line above with the white line above the circuit board; then input 4 mA current (0.02 Mpa), then adjust the zero potentiometer in the transmitter to make the output current 4 mA; Should be less than 1%;

11. Full range detection of 11 position transmitter: input 20 mA current signal (0.1 Mpa), adjust the range potentiometer in the transmitter to make the output current 20 mA, and the error of full range should be less than 1%.

12. Position feedback current full-range deviation calibration: input 4 mA current (0%), then gradually increase the input signal 8 mA current (25%), 12 mA current (50%), 16 mA current (75%) and 20 mA current (100%). Considering the non-linear error of linear displacement conversion to angle change, 0%, 50%, 100% point feedback current error should be less than 1%, 25%, 75% point feedback current error should be less than 2%.

13. Position feedback current forward and backward stroke variation test: the same as cylinder piston forward and backward stroke variation test method, the actual positive and backward position feedback current stroke relationship, the maximum difference of cylinder piston forward and backward stroke value under the same feedback current value is less than 1%.

14. Make a good verification record and fill it in carefully one by one according to the contents of the verification record form. The inspector must sign it.

15 After the above tests are completed, the terminal of the position transmitter should be inserted, the back cover tightened, and then the gas source inlet of the valve positioner should be blocked with a plastic plug.